The 3S MEP + Structural team takes pride in being the top provider of engineering design and drafting services to our customers. We focus on delivering projects which exceed the client’s expectations of timely deliveries, quality, and budget. Our team of engineers has more than a decade of experience working on projects in the United States. With this expertise behind us we can deliver quality products for almost any commercial project.

The 3S MEP + Structural is a leading MEP engineering, design and drafting service that obsesses over delivering results for our clients. We use cutting edge technology such as AutoCAD and Revite suite, to provide clients with strategic solutions.

We provide schematic design, design development drawings, final construction drawings, and a BIM model. Moreover, we follow agile delivery methods, where our team becomes an integral part of the client’s project team.

Because of this, we can proactively adjust the design as each project progresses. Further to this, we deliver a whole-picture through design taking input from all stakeholders.

We aim to be

the world's best

MEP service provider

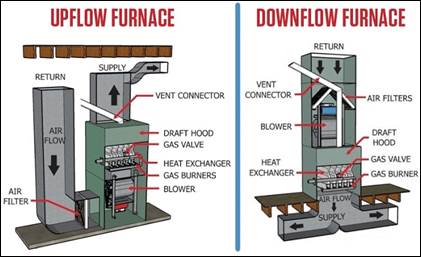

MEP Engineering Services

Revit BIM Services

Structural Engineering Services

Arc Flash Studies